VDU comes as a continuation of the Crude Distillation Unit and thus the feed to VDU is the atmospheric residue from CDU. The feed is vacuum distilled to obtain vacuum gas oil and the vacuum residue is thermally cracked.

The following products are obtained from the unit:

- Vacuum oil from the overhead stream

- Light Vacuum Gas Oil

- Medium Vacuum Gas Oil

- Heavy Vacuum Gas Oil

- Vacuum residue

Purpose: Improving the process conditions so as to meet the flash zone conditions of the vacuum column.

Process: Temperature is raised to about 410OC and the feed is partially vaporized to 30% wt.

Vacuum Distillation Column

Purpose: Distillation and separation of components from the Atmospheric Residue

Process: The partially vaporized feed from the vacuum heater enters the flash zone of the distillation column. The column operates at varying temperature and pressure, from about 360OC and 125 mm Hg at the bottom to 80OC and 85 mm Hg at the top.

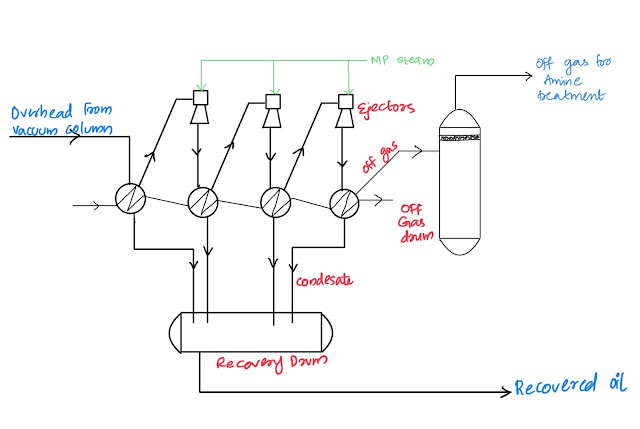

Overhead: Gases from the top are routed through a series of condensers and ejectors.

The condensate from the condensers is drained into a Recovery Drum, where oil and sour water are separated. The recovered oil is usually mixed with the LVGO but can also be taken as a separate product. The non-condensable gases (off-gas),

which are produced due to cracking in the heater are sent to an Off-gas Drum.

The composition of off-gas includes air and lighter hydrocarbons. Therefore,

the off-gas from the off-gas drum is sent for Amine Treating.

The next cut LVGO is drawn from

the top tray. A part of it is returned as pump-around reflux and the remaining

is cooled and taken as LVGO product. LVGO can either be blended with Heavy Atmospheric

Gas Oil (HAGO) and sent for further treatment or can be directly sent to

storage.

MVGO is drawn from a side tray

and usually mixed with HVGO or directly sent to storage.

HVGO is drawn in the next section

and is cooled. Most of the cooled liquid is pumped back as pump-around reflux

and the remaining is taken as the product. MVGO can be blended with HVGO here

and sent for further treatment in the MHC/DHC or can be directly pumped to storage

The column bottom is stripped with

superheated LP steam and the vacuum residue thus obtained is collected at the

bottom. It is then cooled and sent to the Delayed Cocking Unit. A part of the

cooled residue is also sent back as a quench stream in order to control the bottom

temperature so that incipient cracking can be eliminated.

.JPG)

Comments

Post a Comment